6 Products

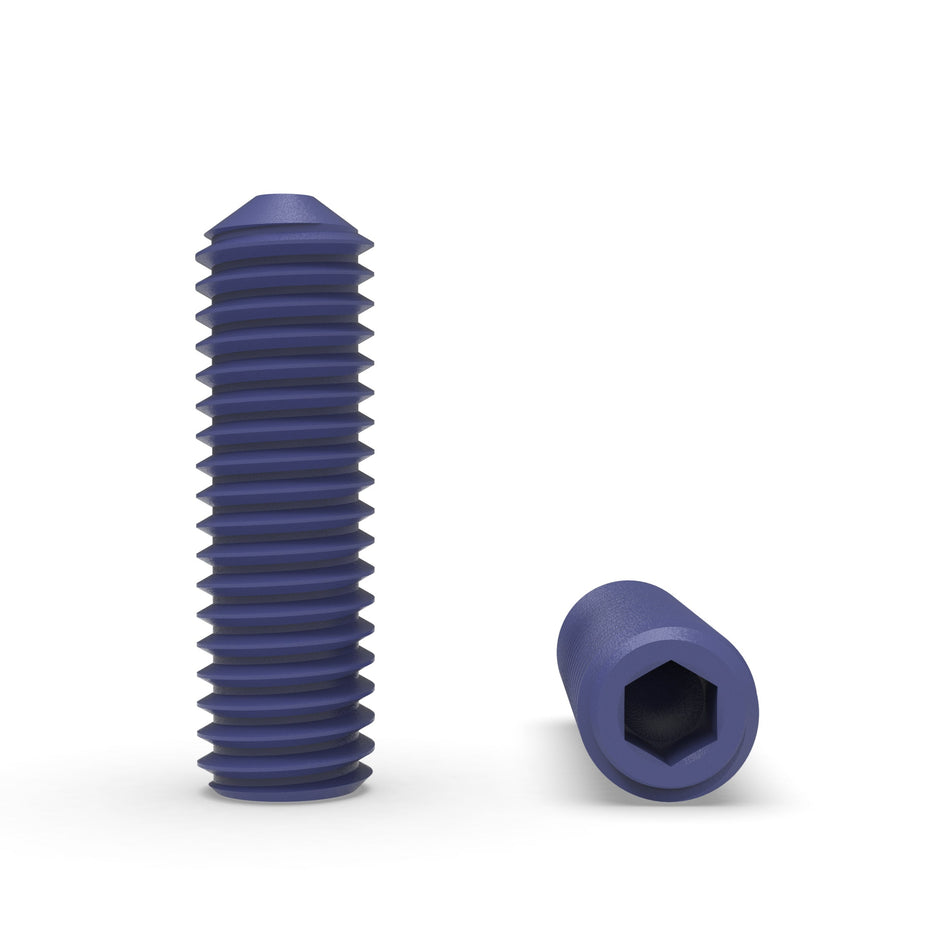

Polymer Grub/Set Screws such as those made of PEEK, RENY, PEEK GF30, PPS, PC, & PVDF for HighPerformancePolymer.co.uk in their Precision Components Range can be used for a variety of different specialised engineering purposes.

High performance polymer grub/set screws are specialised fasteners that are designed to provide exceptional mechanical, thermal, and chemical properties. These screws are made from advanced polymers such as PEEK, PVDF, and RENY, which offer excellent strength, stiffness, and chemical resistance.

One of the key benefits of high performance polymer grub/set screws is their resistance to wear and corrosion. These screws are able to withstand exposure to harsh environments, including chemicals, high temperatures, and high stress. This makes them ideal for use in a wide range of applications, including automotive, aerospace, and medical.

Another benefit of high performance polymer grub/set screws is their ability to reduce weight and increase efficiency in certain applications. Due to their high strength and stiffness, these screws can often replace heavier and less durable metal screws, resulting in a reduction in weight and an increase in efficiency.

In addition, high performance polymer grub/set screws can also provide superior sealing properties when used in conjunction with other components. The polymer material can form a tight seal against mating components, reducing the risk of leaks and improving overall performance.

The design of high performance polymer grub/set screws involves careful consideration of the specific requirements of the application. This includes factors such as the operating environment, the load requirements, and the desired mechanical properties of the component. The design process may also involve the use of computer-aided design (CAD) software to create a detailed 3D model of the component.

Manufacturing of high performance polymer grub/set screws involves specialized production techniques, such as injection molding or CNC machining. These techniques allow for the production of complex shapes and precise dimensions, ensuring that the final product meets the exact requirements of the customer.