Dimension Table

Dimensions for HPLC PEEK Four Way Union/Cross (for 1/16" OD Tubing) in all available sizes are shown according to the product drawing above.

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom left of your screen.

Email:

sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

Material: PEEK

Colour: Natural/Beige

Maximum Temperature: 260°C/500°F

Flammability: UL94 V-0

HPLC PEEK Four Way Union/Cross (for 1/16" OD Tubing) conform to the following Standards/Norms:

The HPLC Four Ways made of PEEK (Polyetheretherketone) are specialised components designed for 1/16" capillary tubes in High-Performance Liquid Chromatography (HPLC) systems. The 1/16" variant has an inner thread size of #10-32 UNF, the 1/8" variant has an inner thread size of #1/4-28 UNF, and the 1/16"to 1/8" variant accommodates both #10-32 to #1/4-28 UNF thread sizes with two ports of each. These four-way connectors provide versatile and reliable connections between capillary tubes and other HPLC system components, ensuring chemical resistance, high mechanical strength, and low extractables, crucial for maintaining the integrity and performance of HPLC analyses.

Total length: 1.13” (28.7mm)

Diameter: 0.37” (9.38mm)

Material: PEEK

Features: Four-way connectivity / Integrated ferrule.

Available sizes: 1/16" #10-32UNF / 1/8" #1/4-28UNF / 1/16" #10-32UNF to 1/8" #1/4-28UNF

Max Pressure: 250 bar / 3600 PSI

Versatility: Allows for complex fluidic configurations by facilitating connections between multiple columns, detectors, or other components within a chromatographic setup. This versatility supports various analytical methods and experimental designs.

System Integration: Enables seamless integration of multiple analytical pathways or detectors into a single chromatographic system, simplifying overall system design and operation.

Improved Stability: The integrated ferrule design provides stability by securely holding the tubing in place, preventing movement or displacement under operating pressures and flow rates. This stability ensures consistent fluidic connections and reliable system performance.

Chemical Compatibility: Made from PEEK, the integrated ferrule maintains excellent chemical resistance to a wide range of solvents, buffers, and mobile phases used in HPLC applications. It prevents material degradation or leaching that could affect sample integrity or system performance.

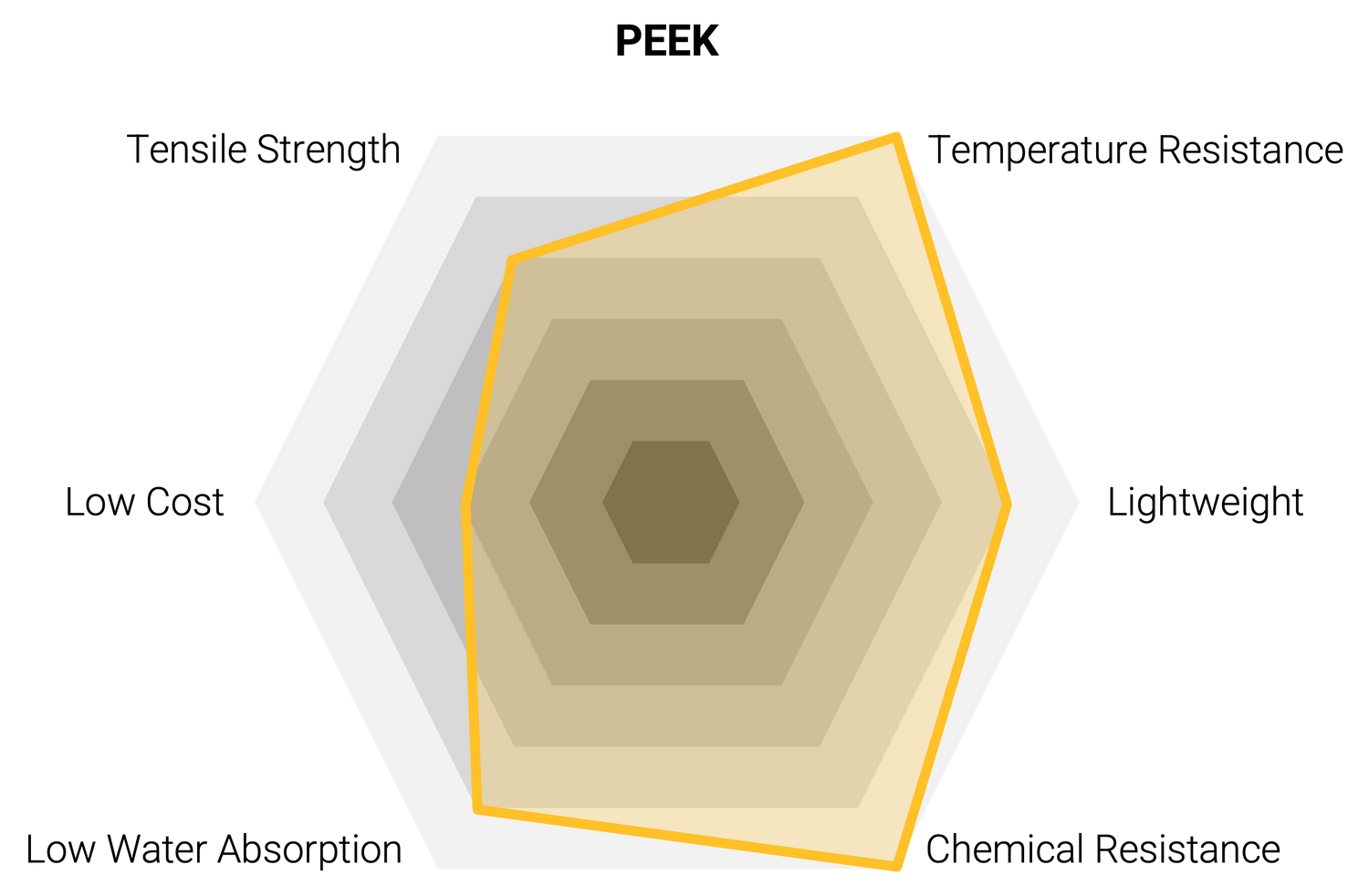

Chemical Resistance: PEEK is highly resistant to a wide range of chemicals, solvents, and acids commonly used in HPLC applications. This ensures compatibility with various mobile phases and sample matrices without degradation, ensuring accurate and reliable analytical results.

Inertness: PEEK is inert and non-reactive, minimizing the risk of introducing contaminants or altering sample composition during chromatographic analysis. This property is crucial for maintaining sample purity and integrity throughout the separation process.

Temperature Stability: PEEK exhibits excellent thermal stability, maintaining its dimensional integrity and mechanical properties over a broad temperature range typically encountered in HPLC systems. It can withstand both high and low temperatures without compromising performance.

Mechanical Strength: PEEK possesses high mechanical strength and stiffness, providing robustness and durability to the Four Way Union/Cross. This strength ensures reliable sealing and prevents leaks under operating pressures in HPLC systems.

Dimensional Stability: PEEK maintains dimensional stability even under fluctuating temperature and pressure conditions, ensuring consistent performance and a secure fit over time. This property contributes to the reliability and longevity of the chromatographic system.

Biocompatibility: PEEK is biocompatible and widely used in medical and pharmaceutical applications. In HPLC, this property ensures that the material does not interact with biological samples or pharmaceutical compounds, maintaining sample safety and purity.

Corrosion Resistance: Unlike metal counterparts, PEEK does not corrode or rust, even in harsh chemical environments or with prolonged exposure to aggressive solvents. This resistance extends the operational life of the Four Way Union/Cross and reduces maintenance needs.

Lightweight: Despite its strength and durability, PEEK is lightweight compared to metals such as stainless steel. This characteristic simplifies handling and installation of components, reducing overall system weight and potential fatigue during operation.

Longevity: Due to its resistance to wear, corrosion, and degradation, PEEK Four Way Union/Cross fittings have a long service life. This longevity minimizes replacement costs and downtime, contributing to cost-effectiveness over time.

Multidimensional Chromatography: Facilitates the connection of multiple columns or detectors in complex chromatographic systems, allowing for comprehensive sample analysis and improved separation efficiency.

Gradient Formation: Essential for creating complex gradient elution profiles by mixing multiple mobile phases or buffers, enabling precise control over the separation of analytes based on their physicochemical properties.

Sample Introduction Systems: Integrates into sample introduction pathways to direct samples to different analytical pathways or detectors, facilitating sequential injections or sample preparation steps.

Valve Actuation Systems: Incorporated into valve systems for directing flow paths within chromatography setups, enabling switching between different sample streams or analytical modes (e.g., isocratic vs. gradient elution).

Parallel Analytical Paths: Allows for simultaneous analysis or comparison of samples across multiple analytical pathways, enhancing throughput and efficiency in analytical laboratories.

Multi-Detector Configurations: Enables the connection of multiple detectors (e.g., UV-Vis, fluorescence, mass spectrometry) to a single chromatographic system for comprehensive sample characterization and detection.

Method Development: Supports method development and optimization by providing flexibility in configuring chromatographic conditions and parameters, such as flow rates, gradient profiles, and column interactions.

Preparative Chromatography: Used in preparative chromatography setups for isolating and purifying target compounds from complex mixtures, suitable for pharmaceutical, biotechnology, and natural product applications.

Automated Chromatographic Systems: Integrated into automated chromatography systems for high-throughput sample analysis, ensuring consistent and reproducible results across multiple samples.

Flow Distribution Systems: Directs flow distribution between different analytical pathways or detectors within a chromatography system, optimizing resource allocation and operational efficiency.

The PEEK data sheet is available as a PDF to download below.

Return components within 90 days for a full refund. Please see returns terms and conditions for further information.

| HPLC PEEK Four Way Union/Cross (for 1/16 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD Tubing Size | Thread Size | Total Length/Width | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/16"-1/16"-1/16" | #10-32 UNF | 1.13" | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8"-1/8"-1/8"-1/8" | #1/4-28 UNF | 1.13" | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/16"-1/8"-1/8" | #10-32 UNF (1/16"), #1/4-28 UNF (1/8") | 1.13" | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dimensions for HPLC PEEK Four Way Union/Cross (for 1/16" OD Tubing) in all available sizes are shown according to the product drawing above.

Follow the link below to view our PEEK data sheet. This includes properties such as mechanical, electrical, thermal and chemical resistance.

Can't find a component?

We can manufacture components to your specification in any of our performance polymer materials. Click on the link, fill out a short form and you'll receive a competitive, no obligation quote within 24 hours.

50,000+ Fasteners In stock

No long lead times. We have a large range of PEEK fasteners available for express delivery (Dispatched the same day if ordered before 3PM Monday-Thursday).

Fasteners not available for express delivery will display the expected delivery date above the 'add to cart' button.

Manufacturer Direct Distributor

We are a manufacturer direct distributor, this allows us to ensure highly competitive prices and keep our shelves stocked. All of our products are manufactured to the highest standards and exhibit exceptional characteristics.

ISO9001 Certified

Certified through Quality Veritas. High Performance Polymer conforms to the ISO9001 quality management system. Certificates available on request.

Material Certificates

We provide full material traceability and can provide certification confirming material data and batch number, which can be traced back to the manufacturer.

Certificate Of Conformity

We also provide a certificate of conformity on request, confirming the product manufacturing standard and material.