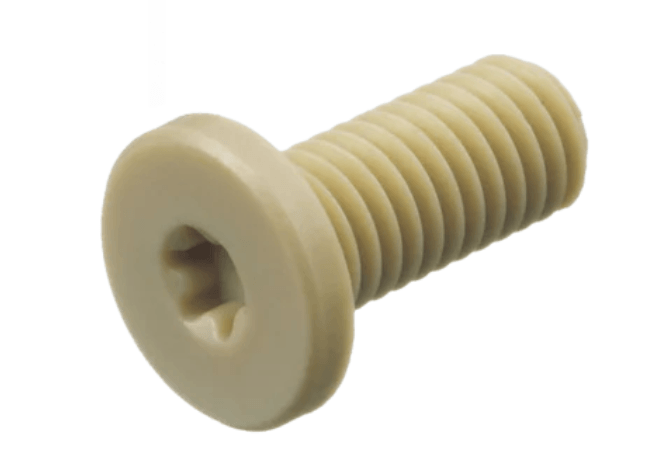

Polypropylene (PP) is a thermoplastic polymer that is commonly used in a wide range of industrial and consumer applications. PP screws, nuts, bolts, and washers are used in many industries because of their excellent chemical resistance, high strength-to-weight ratio, and low cost.

One of the main advantages of PP screws, nuts, bolts, and washers is their chemical resistance. PP is highly resistant to a wide range of chemicals, including acids and bases, making it ideal for use in harsh environments. Additionally, PP has a high strength-to-weight ratio, which means it is both strong and lightweight. This makes it ideal for use in applications where weight is a critical factor, such as in the aerospace industry.

Another benefit of PP screws, nuts, bolts, and washers is that they are non-magnetic and non-conductive, which makes them suitable for use in electronic applications where magnetic or conductive materials could interfere with the operation of the device.

PP screws, nuts, bolts, and washers are also widely used in the automotive industry, where they are used to fasten parts such as engine covers, fuel tanks, and other components. They are also used in the construction industry, where they are used to fasten building materials such as roofing, siding, and decking.

PP screws, nuts, bolts, and washers are also used in the medical industry, where they are used to fasten medical devices such as surgical instruments and implantable devices. They are also used in the food industry, where they are used to fasten food packaging, such as containers and lids.

PP screws, nuts, bolts, and washers are typically made using a process known as injection molding. This process involves injecting molten PP into a mold, where it cools and solidifies. The screws, nuts, bolts, and washers can be made in a variety of sizes and shapes, and can be customized to meet specific requirements.

In summary, Polypropylene (PP) screws, nuts, bolts, and washers are made from a thermoplastic polymer called Polypropylene, which is commonly used in a wide range of industrial and consumer applications. They are known for their chemical resistance, high strength-to-weight ratio, and low cost. They are widely used in Automotive, construction, medical, food and aerospace industry. They are non-magnetic and non-conductive. They are typically made by injection molding and are available in a variety of sizes and shapes.