HPLC PEEK Tubing (1/8" OD, 1000mm)

Want it by XYZ?

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom left of your screen.

Email:

sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

Material: PEEK

Colour: Natural/Beige

Maximum Temperature: 260°C/500°F

Flammability: UL94 V-0

HPLC PEEK Tubing (1/8" OD, 1000mm) conform to the following Standards/Norms:

HPLC Tubing 1/8" made from PEEK (Polyether Ether Ketone) is a specific size of PEEK tubing that finds widespread use in High-Performance Liquid Chromatography (HPLC) equipment. With its exceptional chemical resistance, high-temperature capabilities, and excellent mechanical properties, 1/8" PEEK tubing is well-suited for these analytical instruments.

Total length: 39.37” (1000mm)

Outer Diameter: 1/8” (3.2mm)

Inside Diameters : 1/16" (1.6mm)

Material: PEEK

Features: Biocompatibility / Chemical Compatibility

Biocompatibility:

Sample Integrity: Biocompatible tubing minimises interactions between the tubing material and biological samples. This ensures that the integrity and composition of the samples remain unchanged during analysis, reducing the risk of contamination or sample degradation.

Accurate Results: By maintaining sample integrity, biocompatible tubing helps to ensure accurate analytical results. It prevents adsorption or absorption of analytes onto the tubing surface, which can lead to loss of analytes or inaccurate quantification.

Chemical Compatibility:

Versatility in Solvent Selection: Chemically compatible tubing can withstand exposure to a broad spectrum of solvents used in HPLC analyses, including aqueous, organic, acidic, and basic solutions. This allows for flexibility in solvent selection based on analytical needs without concerns about tubing degradation.

Minimal Adsorption and Absorption: Chemically inert tubing materials have low affinity for analytes, minimising adsorption and absorption of sample components onto the tubing surface. This helps to maintain analyte concentration and improves analytical sensitivity, especially for trace-level analyses.

Manufactured in PEEK:

Compatibility: PEEK tubing is highly resistant to a wide range of solvents, acids, bases, and organic compounds used in chromatography and mass spectrometry. This ensures robust performance and prevents tubing degradation or contamination of samples.

Inertness: PEEK is inert and non-reactive, minimising adsorption and absorption of analytes onto the tubing surface. This property preserves sample integrity, enhances analytical sensitivity, and reduces background noise in chromatographic and mass spectrometric analyses.

Temperature Stability: PEEK tubing maintains dimensional stability and mechanical properties over a broad temperature range (-196°C to +260°C), suitable for both cryogenic and high-temperature applications encountered in GC-MS systems.

Mechanical Strength: PEEK tubing offers high tensile strength, toughness, and fatigue resistance, ensuring durability and reliability in demanding analytical environments. It withstands mechanical stresses, such as pressure fluctuations and handling during installation.

Flexibility: PEEK tubing is flexible and easy to manipulate, facilitating smooth installation and connection within chromatography systems. It allows for precise routing of fluidic pathways without kinking or bending, enhancing system reliability and operational efficiency.

Biocompatibility: PEEK is biocompatible and widely used in biomedical and pharmaceutical applications. In GC-MS tubing, this property ensures that the tubing material does not interact with biological samples or pharmaceutical compounds, maintaining sample safety and analysis reliability.

Low Extractable's: PEEK tubing has low levels of extractable and leachable, minimising interference in analytical measurements and ensuring reproducible results. This property is crucial for sensitive analyses where trace-level detection is required.

Longevity: Due to its resistance to wear, corrosion, and chemical degradation, PEEK tubing has a long service life. It reduces the frequency of tubing replacement, minimising downtime and maintenance costs in analytical laboratories.

Regulatory Compliance: PEEK tubing complies with regulatory standards for materials used in analytical instruments and medical devices. It meets requirements for chemical resistance, biocompatibility, and safety, ensuring adherence to industry regulations.

HPLC PEEK GC-MS Tubing applications:

Pharmaceutical Analysis: Used for the analysis of drug compounds, metabolites, and impurities in pharmaceutical formulations.

Environmental Monitoring: For the detection and quantification of pollutants, pesticides, and contaminants in environmental samples.

Food and Beverage Testing: Analysing food additives, contaminants, and flavour compounds in food and beverage products.

Clinical Diagnostics: For the analysis of biomarkers, metabolites, and therapeutic drug monitoring in clinical samples.

Forensic Science: Used in forensic laboratories for the identification and analysis of trace evidence and controlled substances.

Material Science: Analysing polymer additives, coatings, and surface treatments in material science research.

Chemical Research: Investigating reaction kinetics, product purity, and compound identification in chemical synthesis.

Biomedical Research: Used in research laboratories for biomolecular analysis, proteomics, and genomics studies.

The PEEK data sheet is available as a PDF to download below.

Return components within 90 days for a full refund. Please see returns terms and conditions for further information.

Polyether Ether Ketone (PEEK) Datasheet

Follow the link below to view our PEEK data sheet. This includes properties such as mechanical, electrical, thermal and chemical resistance.

Custom Manufacturing

Can't find a component?

We can manufacture components to your specification in any of our performance polymer materials. Click on the link, fill out a short form and you'll receive a competitive, no obligation quote within 24 hours.

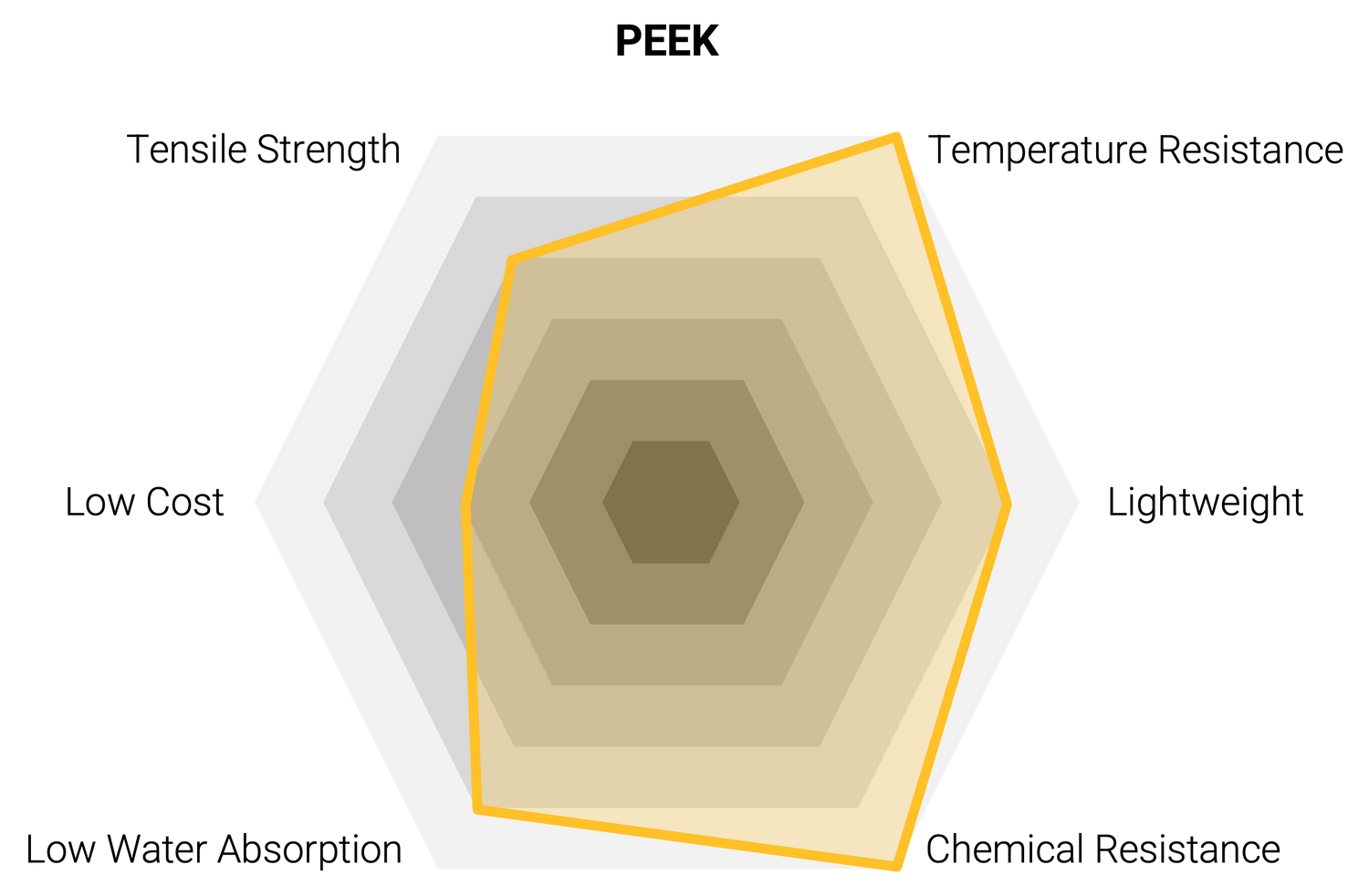

PEEK Key Properties

Why Choose High Performance Polymer?

-

50,000+ Fasteners In stock

No long lead times. We have a large range of PEEK fasteners available for express delivery (Dispatched the same day if ordered before 3PM Monday-Thursday).

Fasteners not available for express delivery will display the expected delivery date above the 'add to cart' button.

Manufacturer Direct DistributorWe are a manufacturer direct distributor, this allows us to ensure highly competitive prices and keep our shelves stocked. All of our products are manufactured to the highest standards and exhibit exceptional characteristics.

ISO9001 CertifiedCertified through Quality Veritas. High Performance Polymer conforms to the ISO9001 quality management system. Certificates available on request.

-

Material Certificates

We provide full material traceability and can provide certification confirming material data and batch number, which can be traced back to the manufacturer.

Certificate Of ConformityWe also provide a certificate of conformity on request, confirming the product manufacturing standard and material.